The BlastPro BP-505 shot blasting machine is designed to clean steel and features modular construction that allows the machine to be dismantled and fit through a 24” manhole. The BP-505 is the most environmentally friendly and cost effective way to clean and profile horizontal steel surfaces that also facilitates the immediate application of coatings. It features independent drives for each wheel which offers better turning capability.

Advantages

- The equipment and all wear parts are manufactured in the U.S.A and there is typically no lead time when ordering parts

- The electrical box and electrical components are engineered and constructed by a UL508A Panel Facility

- Electrical enclosures are built to NEMA 4 specifications

- The positive sealing shot valve prevents shot from leaking even when using very small shot

- The interlocking liners protect the blast housing and reduce wear

- The sliding cleanout drawer is designed to quickly and easily remove debris from the shot hopper

- The improved separation system keeps shot cleaner and increase the life of wear parts

- The type W 4/4 electrical cord is the toughest and most wear resistant cord availabl

- Production Capacity:

- SSPC-SP6 825-1200sq.ft/hr SSPC-SP10 425-800sq.ft/hr

- Blast Pattern:

- 20"

- Travel Speed:

- 0-50ft/min

- Motor:

- 30hp

- Voltage:

- 400/440/480 3-phase

- Amperage:

- 50-60Hz 32 amps

- Min. Generator:

- 75KW

- Machine Dimensions (LxWxH):

- 68x29.5x65in

- Weight:

- 2200lbs

- Dust Collection:

- On-board

- Seals:

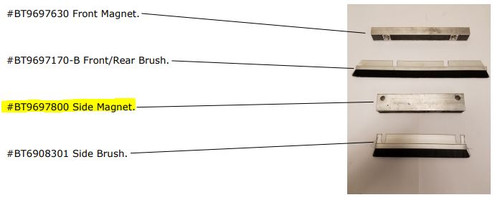

- Floating liner, Urethane, Neoprene & Brush System

- Distance to Edge:

- 4"

- Power Cord Length:

- 100ft